3 things to consider when automating assembly and handling processes

Automate assembly and handling – efficiency, precision and scalability for your manufacturing

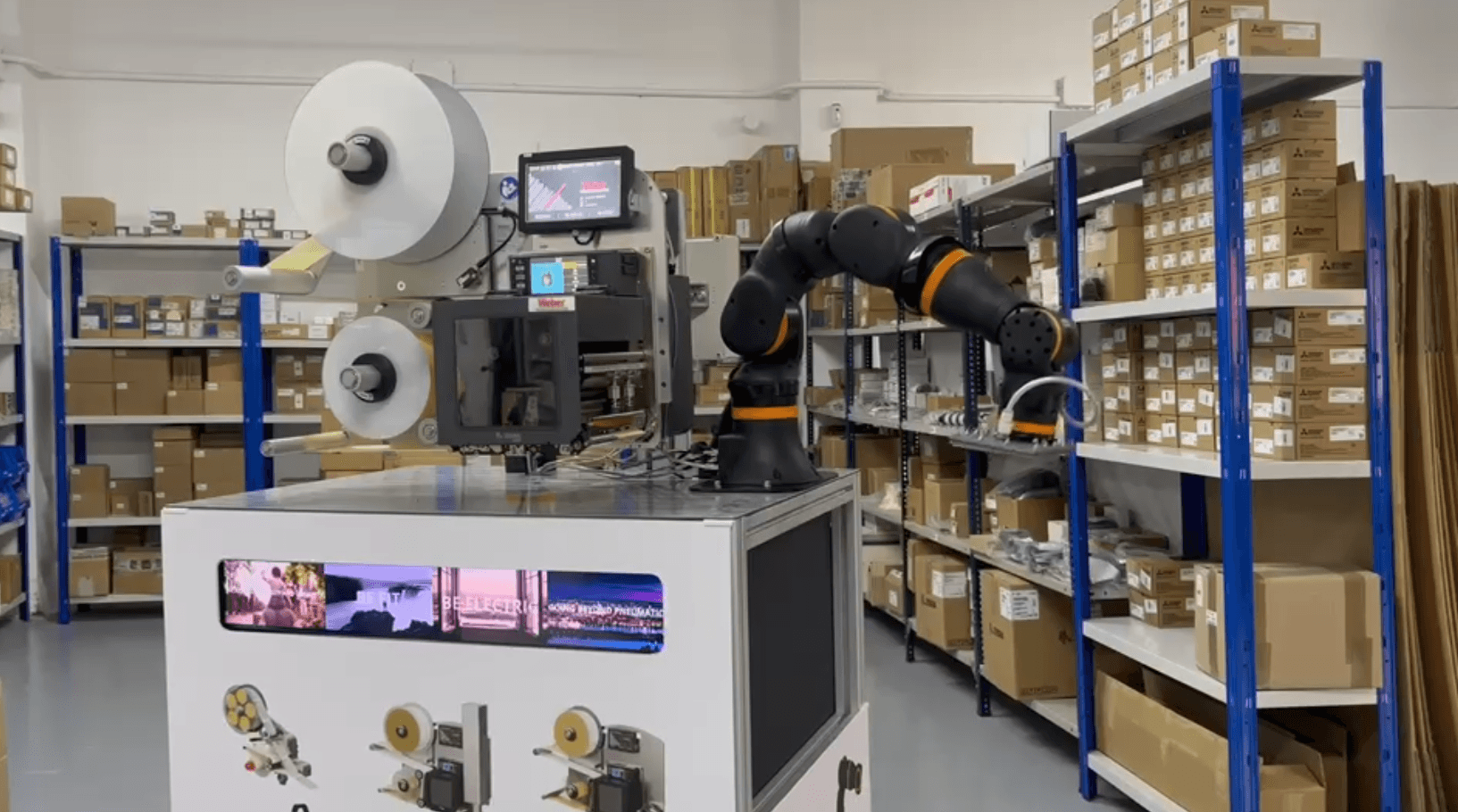

Assembly and handling processes are the backbone of many industrial manufacturing operations. Whether screwing, plugging, joining, testing or positioning – these activities are often repetitive, time-critical and prone to errors. Automating these processes offers enormous potential: it increases productivity, improves quality and reduces the workload on employees.

With the modular and cost-effective solutions available on the RBTX marketplace from igus, companies of all sizes can automate their assembly and handling processes – easily, flexibly and economically.

3 things to consider when automating assembly and handling processes

Process analysis and cycle time determination

Which work steps are particularly time-consuming or prone to errors? Which cycle times must be adhered to? A precise analysis helps to identify the right automation steps – e.g. screwing, pressing, positioning or testing.

Check component compatibility and interfaces

Automation solutions must be compatible with existing machines, workpiece carriers and controls. Look for open interfaces, standardised protocols (e.g. IO-Link, Modbus, Ethernet/IP) and modular design.

Consider flexibility and variety

Assembly often involves product changes or variants. Systems with interchangeable grippers, adaptive control or AI-supported image recognition enable flexible adaptation – without long changeover times.

How to get started with your automation solution

Discover the keys to starting your automation solution: define your application, find the right components on the RBTX marketplace, benefit from testing and consulting, and ensure smooth integration and commissioning

Define the application

Which tasks should be automated? What are the requirements in terms of accuracy, speed, force and flexibility?

Select the right components On the RBTX marketplace, you will find:

Robotic arms (cobots, SCARA, 6-axis) – Grippers, screwdrivers, presses, sensors – Conveyor technology, vision systems, controllers – Complete solutions for assembly cells

Use tests & consulting

Use the RBTX Lab to have your application tested or get advice from experts – free of charge and without obligation.

Integration & commissioning

Many systems are ‘plug & play’ and can be integrated into existing production lines with minimal effort. igus offers support, training and online tools for configuration.

RBTXpert Conclusion

Assembly processes are often complex - many small steps, many variants. Don't try to automate everything at once. Take a close look at which steps take the most time or go wrong most often - e.g. a screwing process, pressing in a part or positioning it on a carrier. That's exactly where you start. With a modular system from RBTX, you can automate this step - and flexibly expand it later. And remember: the best solution is not the most complicated one, but the one that works simply and helps you immediately.

Advantages of automated assembly and handling processes

Automation in assembly and handling delivers faster cycle times, consistent and repeatable quality, reduced waste, ergonomic support for employees, and uninterrupted 24/7 performance without fatigue

Higher process speed and cycle rate

Accelerated operations enable faster task completion and boost overall output, driving greater efficiency across production lines.

Consistent quality and repeatability

Automated systems ensure consistent results in every cycle, minimise deviations and ensure consistently high standards throughout production.

Reduction of scrap and rework

By minimizing process deviations and improving accuracy, automated systems help ensure materials are used efficiently and corrections are rarely needed.

Ergonomic relief for employees

By automating physically demanding tasks, robotic systems help protect employees from strain and injury, fostering a safer, healthier, and more productive work environment.

24/7 operation without fatigue

Automated systems operate around the clock at a constant level of performance, ensuring consistent output without downtime or loss of efficiency.

Get started, find your solution now!

DOBOT

Elite Robots

Hochschule Niederrhein

BOY

igus

Fairino

Fairino

Fairino

FAQ

Frequently asked questions about the automation of assembly and handling processes