1 / 3

1 / 33D Vision-Guided Machine Tending of Gear Shafts

Hardware Price:

DOF

6

Repeatability

0.03

mm

Max. payload

3

kg

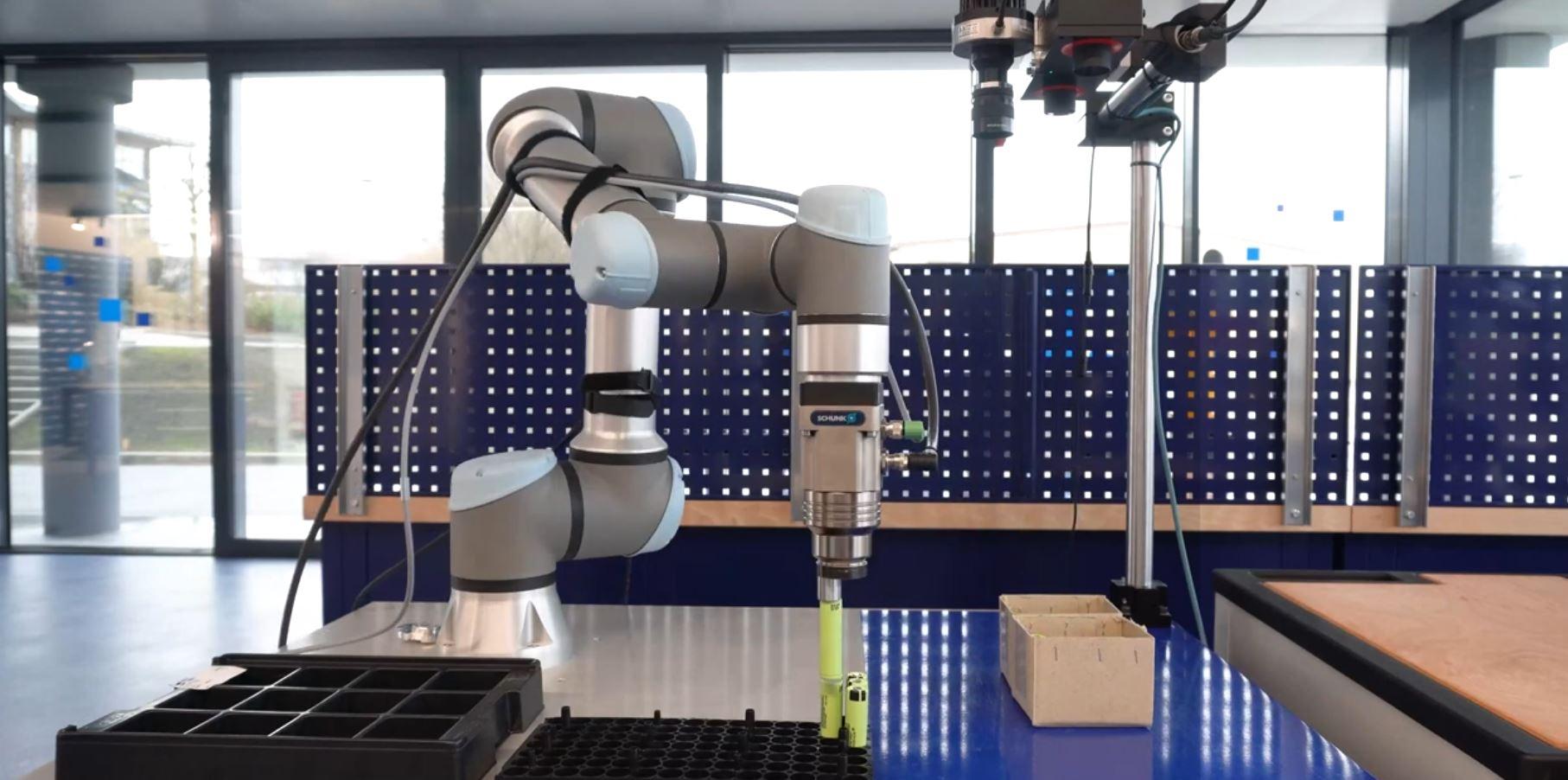

Optimizing Gear Shaft Handling with Intelligent 3D Vision and Robotics

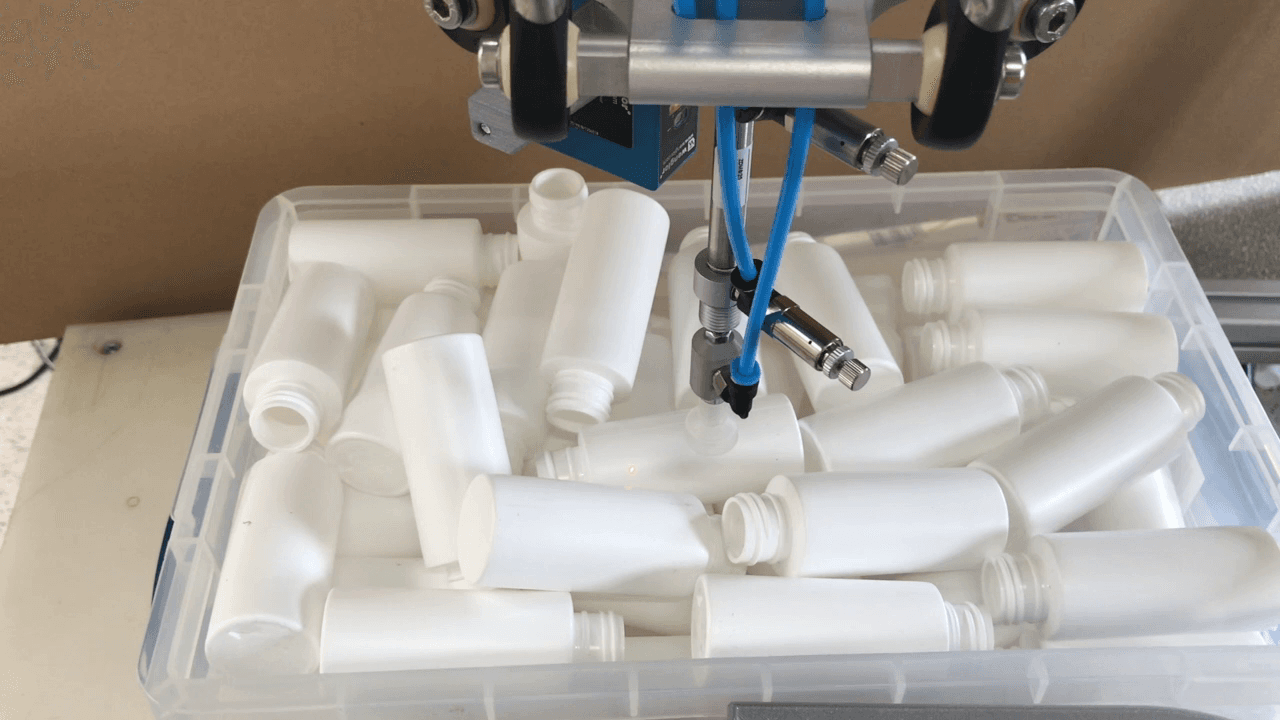

Efficient handling of unsorted components is key in modern manufacturing. This application from 3D vision manufacturer Mech Mind showcases the synergy between intelligent camera systems and the UR3e robotic arm. Gear shafts piled in a blue box are identified by the 3D camera, which transmits their positions to the robot. The robotic arm then picks the gear shafts, places them into an inspection fixture, and sorts them based on quality.

What is the Application?

The system automates gear shaft handling, from picking unsorted parts to placing them for inspection and sorting, ensuring seamless operations in manufacturing.

What are the Advantages of the Solution?

High Accuracy: The 3D camera ensures precise part detection for consistent handling.

Improved Quality Control: Automates inspection and sorting of components.

Versatility: Adapts to varying component shapes and sizes in similar workflows.

What are the Advantages of the Robot?

The UR3e robotic arm and camera integration bring critical benefits:

Precision Movements: Ensures correct placement in fixtures.

Compact Design: Ideal for tight manufacturing spaces.

Reliability: Continuous operation improves production efficiency.

Streamlining Manufacturing with 3D Vision and Robotics

This intelligent combination of a Mech Mind camera system and the UR3e robot revolutionizes gear shaft handling. By automating picking, positioning, and quality control, it enhances accuracy, reduces manual workloads, and boosts productivity, proving an effective solution for dynamic manufacturing environments.

4 Components